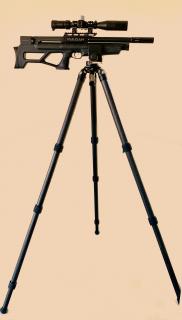

Our Tripods

Building on the best designs in the tripod industry, LF’s tripods combine precision manufacturing with the very best materials to offer a large systematic style tripod that is a pleasure to use and simple to maintain while offering a wide range of modular accessories that won’t break the bank.

Series/Sizes - LF’s tripods starting with a ’36’ are equivalent to 4-series tripods, while a ‘32’ is equivalent to a 3-series and ‘40’ a 5-series. This numbering represents the diameter of the top leg section in mm.

Modular Accessories - One of the key attractions of systematic tripods is the removable apex plate, which can be interchanged with a variety of other accessories. Levelling a tripod’s legs on uneven terrain is a time-consuming pain and a levelling base allows the tripod to be levelled in one quick action. The difference between a standard levelling base and an in-apex version is that this option sits much lower, keeping the tripod’s center of gravity closer to the ground. shooters should look at the clamp less levelling bases with the flat top and mounting screw.

In-Apex Levelling Base Sport Optics and Rifles | When shooting over a long distance, rifles don’t need nearly as much of a motion range as cameras, which allows SOAR users to use a levelling base with a clamp as a pseudo-head. The in-apex levelling bases allow a vertical movement of about 30 + and - up and down (60⁰ of tilt) , with full 360-degree horizontal rotation. Simply connect your picatinny adapter or universal rifle clamp to the levelling base and you’re ready to head to the range.

Modern Apex Design - series tripods feature an apex machined from aircraft-grade aluminum. About 30% of the apex chassis is machined away to save weight, resulting in a hollowed-out design that doesn’t compromise on strength or rigidity. Atop the apex, you will find a standard UNC 3/8” mounting screw compatible with 99% of tripod heads as well as a big, bright spirit level. The bottom features a hook for attaching weight in windy conditions, but the hook can be removed to reveal another UNC 3/8” mounting hole.

The side of the apex features 3 instruments –

- A screw clamp that locks the apex around the base plate/bowl adapter/center column.

- Safety catch with a simple pull-tab to release the base plate/bowl adapter/center column from the apex.

UNC 3/8” Attachment hole for magic arms and other accessories. It also features an anti-flex pin and guide system that corresponds with LF’s AM-series magic arms to avoid sagging when mounting heavy items

Premium Joint Assembly - The legs attach via stainless steel hinge shafts and brass bushings to a machined aluminum hinge chassis – premium materials you won’t see on many tripods in the market today.

Premium Japanese Carbon Fiber - LF uses 10x layer cross-weave carbon fiber tubes made by Toray Inc – one of the world’s top carbon fiber manufacturers. This ensures strength and rigidity while ensuring class-leading weight specifications. The hinges feature self-returning angle-selectors, a small feature that speeds up operation. All tripods offer leg angles of 23, 55 and 85 degrees.

Uncomplicated Joints – All tripod ranges feature fat joints with prominent ribbing to provide great grip and torque for easy loosening and tightening of the joints. One of LF’s proprietary features is a single-piece joint-shim (the shim helps legs to lock together more firmly and prevents the legs from being able to rotate within each other); those who have opened up a twist-joint tripod and seen parts fly will know the frustration of disassembling and reassembling those delicate internal components. All LF tripods feature a one-piece shim, which makes maintenance and cleaning of the joints much easier.

Beveled Aluminum Core Feet – A tripod foot is just a piece of rubber, right? Think again! Most manufacturer’s tripod feet are just a steel spike encased in rubber – this makes it heavy and allows a lot of flex/vibration in the malleable rubber. LF’s engineers have gone to great lengths to make the ultimate tripod foot and the result is an internal aluminum frame that minimizes the amount of flexible rubber in the construction. While this is a tiny detail, it adds to the rigidity of the tripod. All LF ranges’ feet feature a multi-angled bevel, which helps it to grip on uneven

All aluminum components are treated with a hard-anodization process for durability against scratches and bumps.